About us

Providing High Quality PCB Fabrication and Assembly

ApplePCB is among the leading PCB fabrication and assembly manufacturers in China, with over ten years of experience. We possess ten SMT production lines and advanced PCB manufacturing equipment, enabling us to provide reliable PCB production services tailored to exact specifications, accommodating both small and large volume orders.

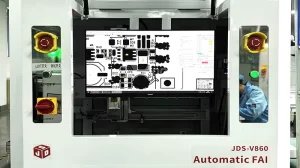

We provide component procurement, SMT, DIP, ICT/FCT testing services, support BGA, QFN, DFM manufacturability inspection, program burning, etc. We use testing and inspection equipment to ensure every product meets our strict quality standards before leaving the factory.

Our sales and quoting team speeds up quotes and orders, ensuring all project files are checked for assembly requirements before starting.

We have established relationships with leading hardware and software vendors and can provide fast and cost-effective board/part sourcing services based on your needs!

Why Choose Us

We shorten your product's time to market by using premium materials and advanced equipment, coupled with our commitment to product quality.

Fast Turnaround

Our team will review your data files and offer a customized quote within 24 hours. After you place your order, we ship your PCB within 10 days using our reliable PCB assembly process.Production Capabilities

We can handle PCB assembly from small to large batches, offering you solutions that are both flexible and scalable. Ensure cost-effectiveness to meet your unique needs.

Quality Control

We have professional engineers and advanced automation equipment, and our QA/QC team monitors every stage of production to ensure the high quality of each board.Excellent Service

Our sales team will collaborate closely with you to ensure your designs are realized as envisioned. We hope to establish lasting relationships by meeting customer expectations.

Mission: To Be Your Reliable PCB Manufacturing and Assembly Supplier

We continuously invest in and upgrade our capacities and equipment to handle PCB boards featuring HDI, Blind vias, Buried Vias, Filled Vias (via-in-pad), Controlled Impedance, Heavy Copper, high aspect ratios, micro-BGAs, along with PCB assemblies that include the smallest package 0201, fine pitch, and BGA assembly.

After your PCB design is finalized, our team will offer free DFM advice, quick-turn PCB prototypes, and prototype PCB assembly services.

When your project is validated by either your engineer or ours, following your testing procedures, and progresses to bulk production, we provide turnkey PCB and assembly services. This encompasses PCB fabrication, sourcing of components, stencil creation, board assembly, and testing. All that is required from you is to supply the Gerber files, BOM, Coordinate file, Assembly Drawing, and Testing Procedures documentation.

Have Questions About Your Project?

Getting a quote is easy—simply complete a form with details of your project, such as the number of assemblies, turn time, and upload the project files. Our team will provide a solution that fulfills your needs, delivering an accurate quote on time and within your budget range.