Your Trusted PCB Assembly Partner

ApplePCB provides reliable PCB assembly services, catering to both quick-turn prototypes and high-volume production runs. There are no minimum quantity restrictions, and prototype assembly can be completed as quickly as within 24 hours. We adhere to RoHS and ISO standards in our production process.

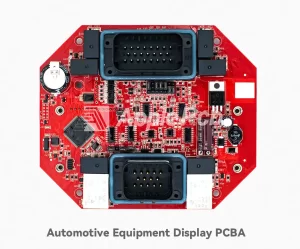

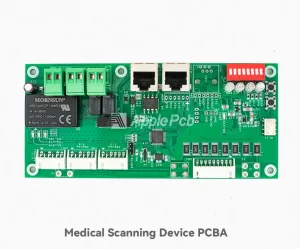

For new product introductions, rapid prototyping needs, and high-volume PCB assembly, we deliver full turnkey solutions. Our factory is equipped with advanced machinery that meets nearly all industry standards. We provide SMT assembly, through-hole assembly, and mixed assembly, and are capable of assembling rigid, flexible, and rigid-flex PCBs.

Furthermore, our team can assist you with component replacements to address obsolete or unavailable parts. We also conduct DFX reviews to ensure continuous product improvement.

Component Sourcing for PCB Assembly

You may choose to provide the components yourself, particularly if you need proprietary parts for devices specific to your brand or protected by a patent.

However, for many projects, clients entrust our experienced assembly teams with component procurement. At ApplePCB, we accommodate both approaches—whether it's a prototype or a full production run. We frequently work under strict non-disclosure agreements when using client-supplied components, but we are equally adept at planning and sourcing the optimal component selection for your needs.

If you prefer the latter, we can negotiate bulk pricing agreements within your budget parameters. With over a decade of industry experience, we maintain strong connections within the dynamic technology supply chain, ensuring efficient procurement processes.

PCB Assembly Process Competences

Our PCB Assembly Services

We offer assembly services, including prototype assembly, turnkey assembly, and both consigned and partially consigned assembly. Our manufacturing capabilities allow us to handle orders of any size, including large quantities.

Prototype Assembly

Our quick turn prototype and assembly services for printed circuit boards cater to small-batch and expedited production needs, providing options for both consignment & turnkey projects.

Production Assembly

Our advanced automated equipment allows for processing production orders, eliminating the need for NRE fees, minimum order quantities, or contractual obligations.

Box Build

We offer box build and electro-mechanical assembly services, including integrating PCBs with other hardware components, cable assembly, wire harnessing, and complete enclosure assembly.

Consigned Assembly (kitted)

We assemble your circuit boards using our advanced automated machinery. You just need to provide all the necessary parts, including the printed circuit boards and electronic components.

Partially Consigned

You provide the custom and stockpiled parts, as well as any additional components. We will help you find the rest of the parts, the PCBs and any missing elements before assembling your printed circuit boards.

Turn-key Assembly

Our team manages the entire service process, from procuring bare printed circuit boards and all essential components to assembly and testing, ensuring it meets the requirements of your application.

PCB Assembly Capabilities

Our factory features multiple assembly lines that enable us to meet complex and stringent requirements on time, all within designated timelines. We maintain quality through inspections and testing conducted at every phase of the assembly process.

PCB Types for Assembly

FR-4 Board

Metal Core Board

Rigid Board

Flexible Board

Rigid-flex board

Parts Procurement

Turnkey PCB Components Sourcing

Partial Turnkey

Kitted/Consigned

Assembly Types

Surface Mount (SMT)

Thru-hole

Mixed Technology

Single or Double-sided Assembly

Large Parts on Both Sides

BGA on Both Sides

Solder Types

Leaded

Lead-free/RoHS Compliant

No-clean Process Available

Stencils

Laser cut Stainless Steel

Nano-coating

Board Dimension

Min Board Size: 50mm x 100mm

Max Board Size: 250mm x 500mm

Component Packaging

Reels

Tray

Cut Tape

Tube (preferred a whole tube)

Loose Parts

Inspections/Testing

Visual Inspection

AOI Inspection

X-Ray Inspection

In-circuit Test

Functional Test

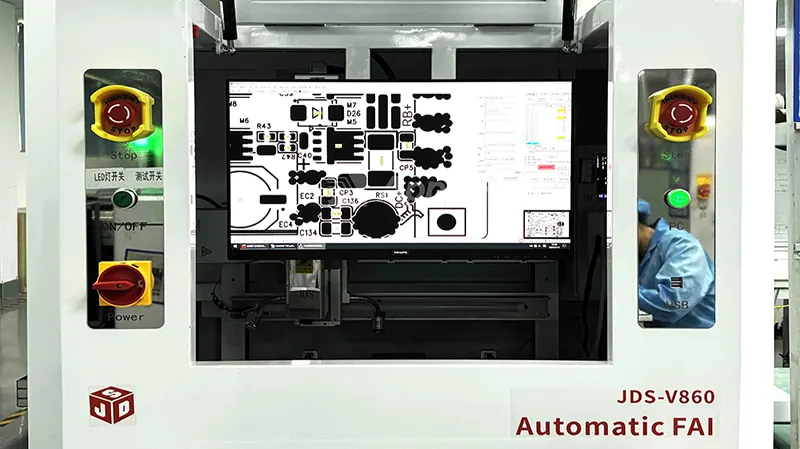

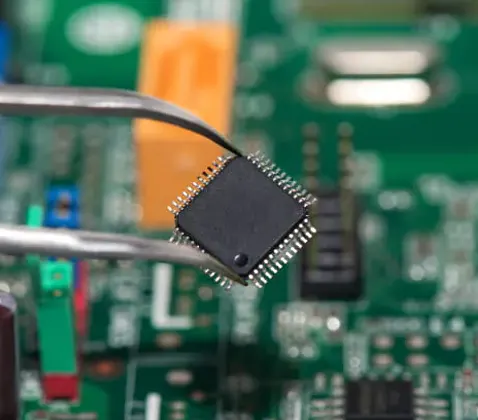

Manufacturing Equipment at ApplePCB

Our advanced factory located in Shenzhen, China, utilizes the latest SMT and THT equipment to produce high-quality and reliable products promptly for our customers. If you need standard quick-turn PCBs or boards requiring the strictest tolerances, crafted from unique metals, ApplePCB's quality and performance will meet your expectations.

Our PCB Assembly Process

- Order Confirmation: Our team will confirm your order details and ensure all necessary files are present.

- Stencil Creation (Optional): If your project requires it, we will manufacture a SMT stencil.

- Machine Programming: Utilizing the BOM and Centroid file, we program our machines before your materials arrive. Any discrepancies within the files will be addressed promptly.

- Kit Audit: Upon receiving all materials, our team conducts a thorough inventory check. We will address any discrepancies or raise further questions at this stage. Please note, all inquiries must be resolved before assembly can commence.

- Lead Time Commencement: To allow sufficient time for the kit audit, the assembly lead time begins the next business day if all materials arrive before 12 PM PST. Materials received after this time will be processed the following business day.

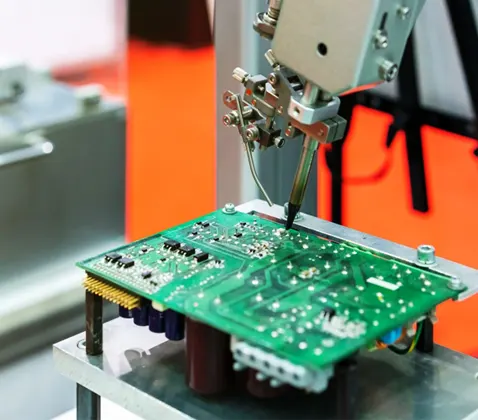

- SMT Assembly: Automated equipment precisely places SMT components onto the board. The initial board undergoes a rigorous QA check to ensure accurate part placement and polarity. As boards exit the reflow oven, they undergo visual and AOI scrutiny.

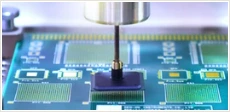

- BGA Verification: We X-ray BGA components to guarantee precise placement and identify any solder bridges.

- Cleaning: If applicable, boards undergo a thorough cleaning process after SMT assembly.

- Thru-Hole Component Insertion: Depending on your project's quantity and design, thru-hole components are either manually inserted and soldered or placed using a selective soldering machine.

- Secondary Cleaning: Following thru-hole assembly, boards may undergo another cleaning cycle if necessary.

- Final Quality Inspection: A comprehensive final inspection ensures the quality and functionality of your assembled boards.

- Packaging and Shipping: We carefully package your completed circuit board assemblies and any remaining materials for shipment. You will receive a tracking number via email to monitor your package's journey.