Visual Quality Inspection

Regardless of the type or application of your printed circuit boards, ensuring their proper functionality is paramount. These boards play a pivotal role in the performance of numerous products, and any malfunctions can lead to significant issues.

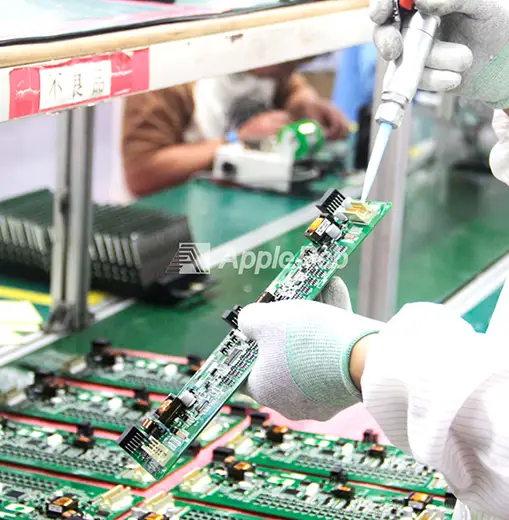

Visual examination serves as a crucial element of quality control during PCB assembly. This process involves a thorough visual review of PCBs to identify any visible defects or imperfections before deployment.

Two primary methods exist for PCB visual inspection: manual and automated. Manual inspection utilizes microscopes and magnifying instruments, while automated inspection employs AOI equipment. AOI systems leverage digital cameras to scan PCBs, aiding in the detection of defects that may be challenging to discern with the unaided eye.

To guarantee quality, ApplePCB utilizes both manual and automated inspection techniques throughout various stages of the PCB assembly process. During these inspections, quality assurance inspectors verify the boards against specific criteria to ensure they meet all required standards.

What is Manual Visual Inspection?

Manual Visual Inspection (MVI) involves scrutinizing a PCB by an inspector to assess its quality and conformity to a benchmark, often referred to as the 'Golden Board,' or against a detailed list of quality control standards. The primary objective of this inspection process is to detect any flaws or deviations from the intended design before the PCB is incorporated into the final product.

Typically, the simplest approach to MVI is using the naked eye, though this method generally detects only the most apparent issues, especially in small or densely populated PCBs. As a result, it is common to examine the boards under a microscope. This approach provides a more thorough and precise examination, allowing the inspector to closely evaluate each detail that constitutes a functional PCB.

Manual Visual Inspection of Assembled Boards

Manual visual inspection represents the most straightforward form of PCB inspection. In this method, an inspector examines the board either directly or using magnification tools. This examination is crucial to verify that the board matches the design documents and meets all specifications.

It is beneficial to carry out manual visual inspections at various stages of the PCB production process, particularly after assembly. At ApplePCB, we ensure that each board undergoes a detailed manual inspection once assembled. Following this, you might consider a more in-depth and advanced inspection.

Our inspection team meticulously examines various aspects of each board to identify common defects. A typical visual PCB inspection checklist might include:

- Verifying the board’s thickness, surface roughness, and any warpage.

- Ensuring the assembly’s dimensions correspond with the specifications, with special attention to the dimensions affecting electrical connectors.

- Evaluating the integrity and clarity of conductive patterns, checking for issues like solder bridging, open circuits, burrs, and voids.

- Inspecting surface quality for pits, dents, scratches, pinholes, and other defects on printing traces and pads.

- Confirming the correct placement of all vias, ensuring they are neither missed nor inaccurately placed, match the diameter specified in the design, and are free from voids or nodules.

- Assessing the pad plating for firmness, roughness, brightness, and any signs of bulging.

- Checking the quality of the coating, including the color and uniformity of the plating flux, and its correct positioning.

While we integrate AOI, electrical tests, and other inspections into our manufacturing process, manual visual inspection remains indispensable for identifying visual defects in base materials, solder masks, silkscreens, and other areas that machines may overlook.

With technological advancements, Automated Visual Inspection (AVI) machines have been developed. These machines employ cameras and software to detect defects on PCBAs, often identifying issues that may be overlooked during manual inspection. AVI proves especially valuable for high-volume production and complex boards due to its ability to quickly and accurately inspect multiple PCBAs.

Visual Inspection Steps for PCB Assembly

Initial Inspection

Begin by examining the bare circuit board for any noticeable flaws, including surface imperfections or structural damage. This step verifies the board's condition, ensuring it is suitable for further assembly processes.

Component Inspection

Next, scrutinize each component for visible defects. Verify part numbers against the assembly documentation and ensure they are free from damage and properly oriented. This part of the process confirms that all components are properly positioned and aligned on the board.

Soldering Inspection

The soldering inspection is a vital part of the process. In this phase, you ensure that all solder joints are correctly formed and that the solder is evenly applied. The inspector looks for any signs of inadequate soldering, including cold solder joints, bridging, or poor wetting.

Final Inspection

The final inspection involves a thorough review of the assembled PCB. This includes checking the placement and soldering of all components, verifying the polarity of components, inspecting for any residual flux, and ensuring that the PCB conforms to all required specifications. This comprehensive check guarantees that the product is fully assembled and meets all quality standards.

Our PCB inspection services are an integral part of our PCB assembly, turnkey box build, and contract manufacturing offerings. These inspections reinforce both our confidence and that of our customers in the product's performance, adhering to IPC-A-600 Class 2 or 3 standards as well as customer-specific requirements. We maintain our inspection processes in strict alignment with the most current industry standards and best practices, ensuring that our inspection team is well-trained, experienced, and equipped with the necessary testing tools.

We are pleased to collaborate with you to customize an inspection process that meets your specific needs and to deliver the high quality of service that your project demands.

Contact Us

Have Questions About Your Project?

Getting a quote is easy—simply complete a form with details of your project, such as the number of assemblies, turn time, and upload the project files. Our team will provide a solution that fulfills your needs, delivering an accurate quote on time and within your budget range.