PCBs and PCBAs play roles in the functionality of contemporary electronic devices. Although they may appear alike on the surface, there exist variances between them. This piece will explore the differences between PCBs and PCBAs, the benefits of incorporating PCBAs in designs, and the wide array of applications for PCBs.

What Is a PCB?

A PCB plays a crucial role in electronic circuits and lacks integrated electronic parts. It is made up of various important components such as the substrate, silk screen, solder mask, conductive layer, pads, and vias. Constructed from laminate materials like fiberglass or composite epoxy, these boards feature conductive paths linking distinct sections. Together, these components are integral to the PCB's performance and structural integrity.

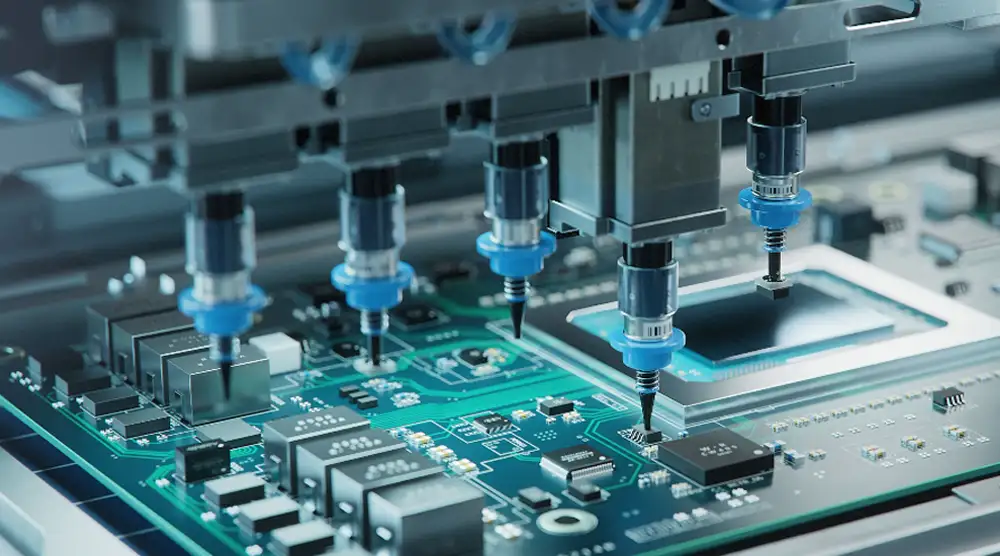

What Is a PCBA?

Printed Circuit Board Assembly, also known as PCBA involves the attachment of components onto a PCB surface to form a complete electronic circuit. This crucial manufacturing step includes soldering the components onto the board turning a PCB into a functional circuit ready for use in devices, like computers, smartphones, medical equipment and automotive electronics.

Difference between PCB and PCBA

PCB and PCBA represent two distinct stages within the same overarching manufacturing process. A PCB is essentially a bare circuit board lacking any electronic components, whereas a PCBA is a fully assembled unit containing all the necessary components for the board to function according to its intended application. While a PCB is inert until components are added, a PCBA is primed for integration into an electronic device.

The production of a blank board is relatively straightforward compared to the complexities involved in assembling a PCBA, given the multitude of components and assembly processes required. Additionally, manufacturing a PCBA typically incurs higher costs compared to producing a bare PCB. Nonetheless, both stages are indispensable in achieving a finalized board, as a PCBA cannot exist without first having a PCB. PCB manufacturing serves as the foundational step, upon which PCBA manufacturing builds.

Furthermore, differences extend to the packaging methods employed for PCBs and PCBAs. PCBs are commonly packaged using vacuum-sealing techniques, while PCBAs necessitate compartmental or anti-static packaging for their components' protection.

Benefits of Incorporating PCBA in Your Design

● Space Efficiency: PCBA can incorporate multiple electronic components onto a single board, optimizing space utilization within your design. This compactness is particularly beneficial for devices with limited internal space or those aiming for sleek and compact designs.

● Enhanced Reliability: PCBA components are soldered onto the board using automated processes, ensuring precise alignment and connection. This results in improved reliability and consistency in performance compared to manual assembly methods, reducing the likelihood of faults or defects.

● Design Flexibility: PCBA offers greater design flexibility, allowing engineers to incorporate complex circuitry and functionalities into their designs with ease. This flexibility enables the creation of innovative and feature-rich electronic products tailored to specific requirements or market demands.

● Scalability: PCBA facilitates scalability, allowing for efficient production scaling to meet varying demand levels. Whether producing small batches or large volumes, PCBA manufacturers can adapt production processes accordingly, ensuring consistent quality and timely delivery.

● Improved Performance: By integrating electronic components onto a single board, PCBA minimizes signal interference and transmission delays, resulting in enhanced overall performance and functionality of the electronic device.

What Are the Applications for PCBs?

Some of the diverse industries where PCBs are utilized include:

1. Automotive: Engine control units, dashboard electronics, navigation systems, and entertainment systems in vehicles heavily rely on PCBs for their operation.

2. Aerospace: PCBs are crucial for avionics, flight control systems, communication equipment, and navigation systems in aircraft and spacecraft.

3. Defense: Military applications utilize PCBs in radar systems, weapon guidance systems, communication devices, and surveillance equipment for national security purposes.

4. Energy: PCBs are integral in power generation systems, renewable energy systems, smart grid technology, and control systems for efficient energy management.

5. Consumer Electronics: Beyond the mentioned radios, printers, calculators, appliances, lighting systems, TVs, cell phones, and video game systems, PCBs are also found in wearable devices, smart home gadgets, and audio-visual equipment.

6. Healthcare: In addition to pacemakers and medical imaging systems, PCBs are employed in patient monitoring devices, diagnostic equipment, laboratory instruments, and medical implants for improved healthcare delivery.

7. Robotics: PCBs are essential components in robotic systems, providing control, communication, and sensory functions for automation in manufacturing, agriculture, healthcare, and logistics.

8. Environmental Monitoring: PCBs play a role in environmental monitoring equipment, such as weather stations, pollution monitoring devices, and remote sensing systems for tracking climate conditions and environmental changes.

9. Telecommunications: Besides telecom towers, PCBs are utilized in network switches, routers, modems, antennas, and other communication infrastructure for reliable data transmission and networking.

10. Internet of Things: PCBs form the backbone of IoT devices, enabling connectivity and data exchange between various smart devices, sensors, and actuators in smart homes, smart cities, and industrial IoT applications.

11. Robotics: PCBs are essential components in robotic systems, providing control, communication, and sensory functions for automation in manufacturing, agriculture, healthcare, and logistics.

Final Thoughts

Both PCBs and PCBAs play essential roles in the realm of electronics manufacturing. It's essentially a symbiotic relationship, as PCBs require components to operate, effectively transforming them into PCBAs, while PCBAs rely on the foundational PCB technology to exist.