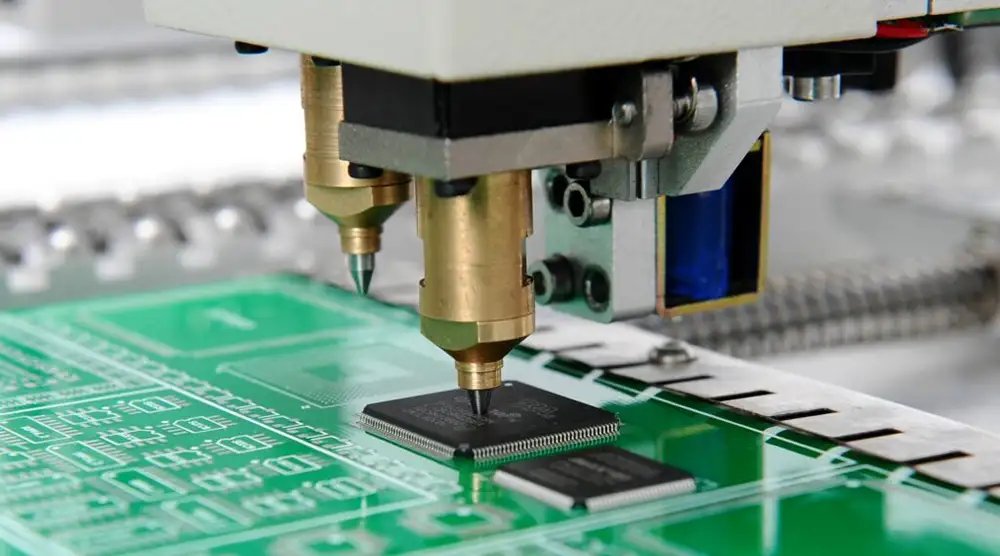

The miniaturization and increasing complexity of modern electronics necessitate advanced assembly techniques. Surface mount technology (SMT) has emerged as a critical solution, enabling the precise placement and soldering of components onto PCBs. This technology plays a vital role in the production of a vast array of electronic devices, from smartphones to sophisticated medical equipment.

From the latest smartphones to basic flip phones, most phone components are likely manufactured using SMT. Let’s take a closer look at what SMT assembly technology is about.

What is SMT Assembly Technology?

SMT marks a step forward in the production of electronic devices. Unlike its predecessor through hole technology (THT) SMT components are directly. Soldered onto the surface of a PCB. This eliminates the requirement for drilling holes and threading component leads, leading to advantages.

State of the art automated systems with measuring and visual capabilities are utilized to accurately position and solder surface mount devices (SMDs) onto the PCB. This ensures precision and consistency throughout the manufacturing process.

One key benefit of SMT over THT lies in its use of space. By doing with through hole components SMT allows for markedly smaller and lighter PCBs. This downsizing enables the creation of intricate electronic devices with compact form factors – an essential consideration for portable gadgets, like smartphones, tablets and smartwatches.

What Are The Advantages Of Surface Mount Technology?

SMT assembly offers advantages compared to traditional through hole technology. It is cost effective allows for designs enhances efficiency, simplifies construction and reduces the likelihood of errors. Lets take a look at each of these benefits:

● Cost Efficiency: SMT cuts down on manufacturing expenses by requiring fewer drilled holes on the circuit board, which reduces processing and waste disposal costs. This makes mass production easier. Improves the cost per unit making SMT a smart economic choice.

● Compact Design: With SMT components can be placed more densely on the circuit board enabling smaller and more compact PCB designs. This is especially beneficial for HDI PCB assembly where optimizing space is crucial.

● Improved Efficiency: SMT not maximizes space usage on PCBs but also speeds up assembly times resulting in higher production output. While, through hole assembly can take 1 2 hours SMT assembly can be completed in 10 15 minutes.

● Simplified Assembly: Through hole technology involves lead wires passing through holes to connect components. In contrast SMT components are directly soldered onto the PCB leading to a simpler overall structure.

● Lower Error Rates: SMT assembly relies heavily on automated machinery reducing human involvement and minimizing the chances of errors occurring. This automation also helps reduce resistance and inductance, in connections, which helps minimize the impact of RF signals and improves performance at frequencies.

What Are The Disadvantages Of Surface Mount Technology?

While SMT offers numerous benefits, it's important to acknowledge some potential disadvantages:

● Reliability Concerns: SMT components solely relying on surface tension for connection may be unreliable under mechanical stress. This is particularly true for connectors frequently subjected to removal and reconnection.

● Susceptibility to Damage: Thermal cycling during operation can potentially damage SMT solder connections. Additionally, the encapsulating compounds may not always withstand the stresses of soldering.

● Space Constraints: SMT's miniaturized nature demands greater operator skill and specialized tools for successful component-level maintenance and manual prototyping. The limited space can increase the risk of errors during assembly.

● Limited Socket Compatibility: Most SMT packages lack socket compatibility, hindering the ease of installation and replacement for faulty components.

● Soldering Challenges: SMT typically utilizes less solder, potentially compromising joint strength and increasing the risk of void formation, which can lead to failures. Additionally, solder's inherent vulnerability to high temperatures and mechanical stress limits SMT's application in specific scenarios.

● Maintenance Difficulties: The reduced size of SMT components often translates to smaller surface areas for identification markings. This can pose challenges during prototyping, repair, and rework processes.

Final Words

When considering SMT assembly for your project, partnering with a qualified and reputable contractor is paramount to mitigating potential challenges. A contractor specializing in design can provide valuable insights into the advantages and disadvantages of SMT compared to through-hole technology, ensuring informed decision-making.

Given the prevalence of SMT assembly in contemporary electronics design, it's worth evaluating if transitioning from through-hole technology could enhance your product's development and competitiveness.