Modern electronic devices get smaller and more powerful, they generate a lot more heat in tight spaces, this is where high Tg PCB comes into play, it can handle higher temperatures and keep everything running smoothly under heat stress.

What Is a High Tg PCB?

The glass transition temperature (Tg) is the point at which the substrate shifts from a rigid state to a rubbery state. High Tg PCB utilize a substrate material designed to endure temperatures exceeding 170°C, some people call it Tg170 PCB.

TG defines the temperature limit for the PCB. It's generally advised to maintain the operating temperature least 20-25°C lower than the Tg value to ensure the rigid state of the material.

A PCB's material turns rubbery-like when its operating temperature goes above its Tg. This change can make the PCB warp or twist maybe hurting its structure and how well it works. The PCB will return back to its normal shape once it cools down below the Tg again.

Choose the Appropriate Tg Value

1. Understanding Tg Value

Higher Tg values are used to denote higher thermal stability of the PCB material, thus, they demonstrate a greater thermal resistance which increases the PCB's service life. In other words, they are less prone to situations like copper delamination, blistering, etc, however, the materials are also likely to be more costly.

2. The Factors Affecting TG Value

Resin Material

Using resins like epoxy, polyimide, or PTFE on the substrate, the TG values differ. Each of them grades higher in cross-linking, which implies that the molecular structure becomes much more tightly bonded and thus, the rigidity and thermal stability are increased.

Filler Content

By the way of embedding thermally stable fillers, for example silica or ceramic, into the resin can increase the Tg.

Manufacturing Process

Increasing the curing temperature and curing time can raise the Tg.

Composite Materials

The use of composite materials, which combine different resins or incorporate materials like glass or carbon fibers, can also enhance the TG value.

3. Common Tg Values for FR4

The FR4 core also known as glass-reinforced epoxy, is typically sandwiched between two layers of copper in PCB, it is generally categorized into three main Tg value classes based on their temperature resistance:

Standard Tg Materials

Standard Tg materials have a Tg value of around 130-140°C. These materials are suitable for most consumer electronics and general-purpose application. Common examples include the SYTECH S1141 and Kingboard KB-6164F laminate.

Medium Tg Materials

Medium Tg materials have a Tg range between 150°C and 170°C. These are often used in application where the board experiences moderate thermal stress. Typical example of medium Tg material include SYTECH S1141 150 and Kingboard KB-6165F.

High Tg Materials

FR4 high Tg materials are capable of withstanding temperatures above 170°C, making them ideal for high-performance application that operate under extreme thermal conditions. These materials provide superior stability and reliability but come at a higher cost. Notable example include the SYTECH S1170 and Kingboard KB-6167F laminate.

4. Assessing Application Requirements

Standard Tg for Consumer Electronic: For most consumer electronics like smartphones, laptops, and home appliance, standard Tg materials are adequate. These device generally operate in environment with moderate temperature range.

Medium Tg for Industrial and Automotive: Application that require enhanced durability, such as industrial control system and automotive electronic, often use medium Tg materials. These materials offer better resistance to thermal stress.

Materials, with high glass transition temperature are well suited for demanding purposes like applications requiring power density or exposure to intense heat. These scenarios typically include aerospace electronics, computing and telecommunications systems.

5. Cost

Creating PCB high Tg results significantly higher expenses because of the combined impact of expensive materials and complex manufacturing processes.

Why Do You Need a High Tg PCB?

Better Than Standard Tg PCB

High Tg PCBs are generally more reliable than standard FR-4 PCB because they have better thermal, chemical, and mechanical properties. This reduces the likelihood of various board failures in high temperature environments.

RoHS Requires Lead-free Solders

The main reason for the high Tg PCB is because of the movement to RoHS Compliant PCBs. The RoHS requires the use of lead-free solders, which requires higher reflow soldering temperatures (≥230°C). High Tg PCB can handle these elevated temperatures without compromising the structural integrity.

Multi-layer and HDI PCBs

High Tg PCBs are essential for multi-layer PCB (especially more than 10 layers) and HDI PCBs because they can withstand the heat generated by densely packed components.

Reduced Signal Loss

High Tg materials often have lower dielectric constant (Dk) and loss tangent (tan δ) values compared to standard FR-4. This translates to reduced signal loss and improved signal integrity, particularly beneficial for high-speed and high-frequency applications like 5G technology.

High TG PCB VS High-speed PCB

High TG PCBs and high speed PCBs represent types of printed circuit boards with different features and uses. High TG PCBs excel in scenarios demanding heat resistance while high speed boards are ideal for transmitting signals. Nevertheless there exists an intersection between them in applications, like telecommunications, where both speed performance and heat endurance are crucial factors.

High TG Materials and Applications

FR-4 High Tg

High Tg FR4 is an upgraded type of FR 4 laminate that consists of woven fiberglass cloth saturated with epoxy resin. With the integration of a Tg resin system, FR4 PCB TG150, FR4 PCB TG170 and FR4 PCB TG180 provide a Tg range usually between 150 to 180°C contrasting with the standard FR 4 Tg range of 130 to 140°C.

This material is ideal for use in scenarios demanding resistance to high temperatures like, in consumer electronics, automotive electronics and general industrial equipment.

Polyimide (PI)

Polyimide is a top notch plastic renowned for its heat resistance ability, electrical insulation properties, strong mechanical properties and resistance to chemicals. It is capable of enduring temperatures high as 260°C.

Commonly employed in cutting edge computing, aerospace ventures, medical equipment and flexible circuitry.

BT Epoxy Resin

Made from bismaleimide triazine (BT) epoxy resin, this material offers excellent high-frequency performance, low dielectric loss, and chemical stability. It typically has a Tg ranging from 200°C to 250°C.

Commonly used in high-temperature applications such as automotive electronics, telecommunications, high-speed digital circuits, advanced computing.

Rogers laminates

They are manufactured by Rogers Corporation. Unlike standard FR4 which uses epoxy resin, rogers laminates often employ a hydrocarbon ceramic resin system, generally have a Tg of greater than 280°C. Used in microwave and radio frequency (RF) applications.

PTFE (Polytetrafluoroethylene)

PTFE-based substrates provide the highest Tg among plastic PCB materials, rated at over 260°C. PTFE is a highly inert fluoropolymer that withstands nearly all chemicals and offers high dielectric strength and excellent electrical insulation.

Ideal for high-frequency applications like radar and communication systems. Despite its superior properties, PTFE is the most expensive high Tg option.

Ceramic-Filled Laminates

Crafted from substances such as aluminum oxide (Al2O3) these laminates are crafted to withstand temperatures surpassing 300°C. They retain their electrical reliability even in environments reaching up to 1000°C offering unparalleled heat resistance and electrical insulation.

These laminates are found in the thermal setting applications, such, as LED lighting, power electronics and space technology. Nonetheless ceramics possess a fragility that poses challenges and expenses in the production of these PCBs.

Challenges of Manufacturing High Tg PCB

Precision Lamination Processes

High Tg printed circuit boards frequently feature multi-layer that necessitates precise alignment and meticulous lamination processes.

Drilling Challenges

Drilling on high TG material can lead to challenge, like uneven surface, sharp edge and leftover particle which can hinder the process of creating clean and accurate pathway.

Advanced Materials

High temperature PCB is crafted using the laminates with advanced material that can withstand higher temperatures, like BT epoxies or polyimides. High Tg PCB manufacturer must source these laminates from reliable suppliers who meet stringent specifications such as UL and Rohs, this makes sourcing high Tg materials more complex and time-consuming.

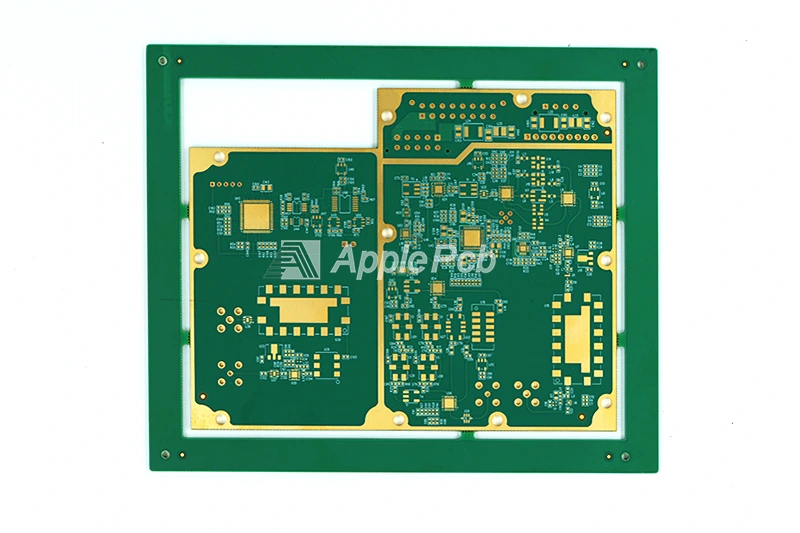

Explore Our Capabilities

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 1 - 40layers |

| Order Quantity | 1 pc-10000+pcs |

| Build Time | 2days - 5weeks |

| Material | KB6167F, S1141 (FR4), S1000-2M (FR4), IT180, Rogers 4350B, and more |

| Board Size | Min 6mm x 6mm | Max 500mm x 1500mm |

| Board Thickness | 0.2mm - 8mm |

| Copper Weight (Finished) | 0.5oz-20oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Color | White, Black, Yellow, etc. |

| Surface Finish | HASL - Hot Air Solder Leveling |

| Lead Free HASL - RoHS | |

| ENIG - Electroless Nickle/lmmersion Gold - RoHS | |

| Immersion Silver - RoHS | |

| Immersion Tin - RoHS | |

| OSP - Organic Solderability Preservatives - RoHS | |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | Machine Drill: 0.15mm |

| Laser Drill: 0.075mm | |

| Other Techniques | Gold fingers |

| Blind/Buried Vias | |

| Countersink Holes | |

| Testing Methods | AOI |

| Flying Probe | |

| In-Circuit | |

| X-Ray Inspection | |

| Functional Testing | |

| Certifications | IATF 16949:2016 |

| ISO 9001:2015 | |

| ISO 14001:2015 | |

| ISO 13485:2016 | |

| UL |

Why Choose ApplePCB?

Expert Guidance

ApplePCB has a group of engineers who have a lot of knowledge in creating high Tg PCB. They carefully choose the materials based on your applications temperature needs. If you're not sure if you need Tg PCB for your operations our experts can help you figure it out.

Selected High Tg Laminates

At ApplePCB, we choose only the highest quality heat-resistant laminates complying with RoHS standards from renowned companies like Rogers, Kingboard, SYTECH, Ventec, Isola and more to manufacture our high Tg PCB.

| Manufacturer | Model | Tg value |

| Isola | 370HR | 200°C |

| Rogers | N4380-13RF | 200°C |

| Rogers | RO4350B | 280°C |

| Rogers | RO4003C | 280°C |

| SYTECH | S1141(FR4) | 175°C |

| SYTECH | S1000-2M (FR4) | 180°C |

| SYTECH | S1150G | 155°C |

| SYTECH | S1170G | 180°C (DMA) |

| ITEQ | IT180 | 180°C |

| Kingboard | KB-6167F | 170°C |

Commitment to Quality in Any Production Volume

Whether you require prototype PCB or are in need of large scale production we always prioritize maintaining the standards of product quality. The satisfaction expressed by our array of customers serves as a true reflection of our success.

Experience Across Diverse Industries

We have expericens of producing PCBs for various purposes such as automotive electronics, industrial control systems, telecommunications, medical devices and RF and microwave circuits. No matter what your application is, we've got the solutions to suit your requirements.

RoHS Compliant PCBs

We exclusively utilize materials that're RoHS compliant from verified suppliers and offer comprehensive RoHS documentation with each batch of PCBs complete, with certificates and clear labels. Furthermore our wide range of surface finishes that adhere to RoHS standards guarantee top notch performance.