The advancement of PCB technology has driven the development of multiple advanced technologies, including the continuous innovation of LED PCBs. These specialized boards serve as the foundation for LED lighting systems. Regardless of the diverse array of LED lights available, each one relies on an LED PCB as its central component.

We provide professional LED PCB assembly services, offering comprehensive solutions for your LED lamp and lantern requirements. We ensure that each circuit board produces fully adheres to your design specifications.

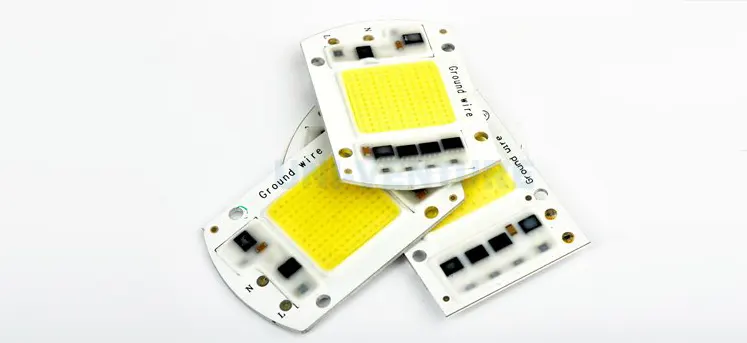

LED PCB

LED, short for Light-Emitting Diode, is a type of semiconductor diode that emits light when an electrical current passes through it. In practical applications LEDs are affixed to PCBs. Paired with a chip that enables light emission through electrical connections. The chip is linked to the PCB via a heat sink and ceramic base. It's safe to say that LED PCBs are the foundation of any LED lighting system.

Nevertheless LED PCBs generate heat posing challenges, for traditional cooling methods. This is where metal core PCBs, particularly those made of aluminum, come into play. Their exceptional heat dissipation properties make them well suited for LED applications. Typically an aluminum PCB includes a layer of thermally conductive material that effectively transfers and disperses heat surpassing conventional rigid PCBs in this aspect.

Currently, surface mount packaging is the most prevalent form of LED packaging used in LED applications. Since the light emitted by a single LED component is often limited, multiple LEDs are typically used in a luminaire to achieve the desired level of brightness. Similar to other semiconductor devices, LEDs rely on PCBs to provide optimal electrical connections. These specialized PCBs populated with LED components are commonly referred to as "LED PCBs."

LED PCB Assembly Methods

When assembling LED light circuit boards, you have two main options for attaching electronic components and LEDs to the printed circuit boards: Surface-Mount Assembly and Thru-hole Assembly. Each method offers distinct advantages and suits different applications.

Surface-Mount Assembly:

This highly automated process involves mounting components directly onto the board's surface. It allows for excellent flexibility and enables high-density connections, making it ideal for complex LED applications with smaller footprints.

The SMA process unfolds in several stages:

1. Solder paste application: A precise stencil deposits solder paste onto the designated areas of the board.

2. Pick-and-place: Automated machinery precisely positions the components onto the solder paste.

3. Soldering: The board and components undergo controlled heating, melting the solder and forming secure connections.

4. Testing and inspection: The board is thoroughly tested to ensure proper functionality and identify any potential issues.

Surface-Mount LED circuit boards are particularly well-suited for intricate circuitry within compact devices.

Thru-hole Assembly:

This technique involves drilling holes in the PCB, inserting the components through these holes, and then soldering them in place. This method creates robust and durable connections, making it suitable for equipment operating in harsh environments or high temperatures.

While THA offers excellent strength, it requires more manual labor and individual component placement. To guarantee quality and performance, multiple inspections are conducted throughout the assembly process.

Quality LED PCB Assembly Services

We offer one-stop LED PCB assembly services encompassing all phases from component procurement and design to assembly and testing. Situated in Shenzhen, China, our facility features automated assembly lines equipped with pick and place machines. These machines have the capability to handle up to 45,300 components per hour and can place components with pitches as small as 0.2mm. Our Experienced LED assembly technicians ensure the delivery of efficient and top-quality LED lighting products.

ApplePCB also possess a range of advanced equipment, including several reflow ovens, selective soldering machines, 3D solder paste inspection, and 3D automatic optical and X-ray inspection systems. We also prioritize environmental sustainability and component integrity by offering eco-friendly circuit board cleaning using recycled de-ionized water, ROSE testing for quality assurance, and humidity-regulated storage to protect moisture-sensitive components.

ApplePCB’s LED PCB Assembly Capabilities

Being a reliable manufacturer of LED PCBs, we assist our customers in transforming their complex designs into tangible products. These capabilities enable us to deliver your order accurately and on time.

● Board Types: Flexible, rigid, and rigid-flex options.

● Materials: Choose from a wide range of materials such as FR4, FR-406, 370 HR, Teflon, Rogers RO4350, RO4003, polyamide, Clad thermal substrates, Hybrid (FR4 and Rogers), aluminum, and copper base.

● PCB Finishes: Including HASL (leaded and lead-free), nickel flash gold, electroless soft gold, wire bondable soft gold, immersion gold OSP, electrolytic hard/nickel gold, immersion tin/silver, ENIG, and carbon ink.

● Circuit Layer: Typical circuit layer thickness is 1.4Mil (.0014").

● Dielectric Thickness: .003".

● Base Plate (Cu or AI): Base plate thickness is 0.057".

● Dielectric Thermal Conductivity: 1 to 30 W/mk.

● PCB Cores: Choose from FR-4, Epoxies, and aluminum laminated with copper for PCB cores.

● Panelized PCBs: Various panelization options, including tab routed, breakaway tabs, V-scored, and routed+ V scored.

Why Choose ApplePCB for Your PCB Assembly Requirements?

For many years, we have been providing our global customers with satisfying LED PCB assembly results, consistently aiming to exceed expectations with our products and services.

1. PCB Assembly Types: We offer a full spectrum of PCB assembly services, encompassing THT, SMT, mixed assembly, and various package types including rigid, flexible, rigid-flex, and Package on Package (POP).

2. Rapid Turnaround Times: Our standard lead times range from 1-5 days, while complex projects can be completed within 1-2 weeks. Leveraging our Open Parts Library (OPL) can further expedite delivery.

3. Commitment to Quality: We partner with renowned LED chip manufacturers like CREE, Samsung, Osram, and Lumileds, ensuring the authenticity and quality of our LED chips. Every PCB assembly undergoes rigorous testing and inspection, including X-ray, in-circuit testing (ICT), functional testing, and AOI, guaranteeing 100% quality assurance.

4. Flexible Production Capabilities: Whether you need a single prototype or large-scale production exceeding 10,000 units, our experienced team is equipped to handle projects of all sizes.

5. Tailored Solutions: PCB assembly needs differ across industries, we offer custom solutions to meet your specific requirements. Our experts collaborate closely with you to understand your needs and recommend the most suitable approach.

6. Dedicated Customer Support: We prioritize customer satisfaction. You'll be assigned a dedicated project manager who will work alongside our assembly and engineering teams to ensure a seamless experience.

7. Timely Delivery: Our advanced facilities and streamlined in-house manufacturing processes enable us to consistently deliver products on time.

As a trusted LED PCB assembly manufacturer in China, we take pride in delivering high-performance, reliable LED PCBs. Contact us today and let us apply our cost-saving assembly techniques to your next LED project.