PCB prototype assembly, also known as PCB sample assembly, SMT PCB prototype, or PCBA prototype assembly, is a crucial step in validating new electronic designs. By creating a functional sample, you can evaluate its performance, identify any flaws or bugs, and make necessary adjustments before committing to mass production. Typically, an electronic project may go through 2-3 rounds of SMT assembly, ensuring everything operates flawlessly before full-scale manufacturing begins.

ApplePCB provides customized PCB prototype assembly and component procurement services. We translate your unique PCB designs into tangible prototypes through a streamlined and cost-effective process. Our comprehensive testing procedures guarantee that your prototypes meet your exact performance specifications. By entrusting your PCB assembly to us, you can save precious time, resources, and avoid potential hassles.

Benefits Of Prototype PCB Assembly

Creating prototypes of PCBs offers substantial advantages during the product design phase. The following are some of the primary benefits:

1. Quality Assurance and Bug Fixing: Prototype PCB assembly presents a budget-friendly approach to evaluate your design and uncover any flaws before committing to mass production. This practice helps minimize the chances of expensive mistakes and production delays, ultimately conserving both time and resources, while simultaneously elevating the overall quality of the final product.

2. Design Enhancement and Functionality Boost: Examining a PCB prototype allows you to observe how the design performs in real-world scenarios. By implementing necessary modifications to the prototype, you can refine the design and enhance the functionality of the final product. This leads to superior end products that boast increased reliability and effectiveness.

Quick-turn and low-cost Prototype Assembly Services

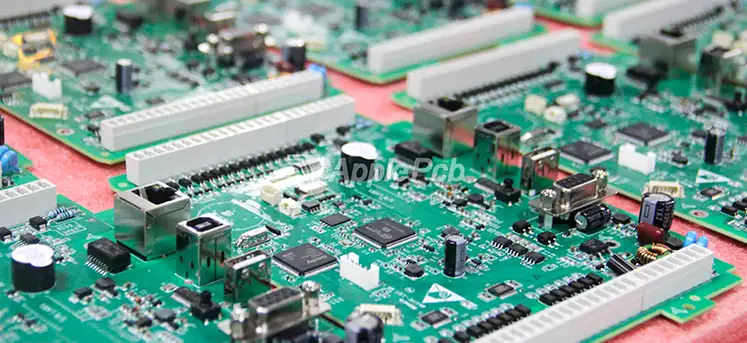

We provide professional prototype PCB assembly services. We can take your intricate designs, prepare them for assembly, and thoroughly test them, so you can rest assured that the workmanship will meet your high standards. The layout of our prototype PCB assembly section is uniquely designed to allow the flexible use of both automated and manual parts-loading stations. Our skilled technicians possess extensive experience in handling delicate, fine-pitch components and BGAs commonly found on high-density FR-4 PCBs.

From the initial prototype phase, ApplePCB offers turnkey circuit board assembly services. Our team of skilled engineers has established efficient procedures for every phase of the PCB manufacturing process. This allows our customers to benefit from our circuit board prototyping, parts procurement, and PCB assembly services. Additionally, we offer a partial turn-key service option, where we can assemble component kits based on your specific requirements.

Our PCB Assembly service offers prototype assembly without requiring a minimum order, along with complimentary DFM service, a diverse range of materials, and component sourcing. This frees you up to focus on what you excel at designing the layout. Our dedicated sourcing team collaborates with numerous suppliers and distributors to acquire components according to your exact specifications, ensuring efficiency throughout the procurement process. We employ advanced methods to choose the optimal packaging formats (cut tape, tube, bulk, etc.) to minimize overall costs.

Additionally, we possess the capability to cross-reference components and locate those that are difficult to find or obsolete. Rest assured, when ApplePCB suggests component substitutions, they are of high quality as we adhere strictly to the component numbers and manufacturers specified in your BOM. We will never alter your original layout design, and part substitutions only occur with your explicit approval.

We understand the significance of swift delivery. Acquiring components quickly allows us to initiate circuit board fabrication promptly. Before starting the assembly process, we engage in discussions with our clients to address any engineering inquiries or component-related concerns they may have. Typically, turn-key PCB assembly takes approximately two weeks. However, this timeframe can be shortened if all necessary components are readily available and the documentation is free of errors.

The Prototype PCB Assembly Process

The assembly of a prototype PCB progresses through different stages to create a functional prototype. Here are the crucial steps in this process:

1. Design and File Preparation

This involves sketching out the circuit diagram, arranging the components within a specialized software program, , and creating Gerber files for production. Ensuring your design is optimized for both production and assembly is key, as is including all the necessary connections and components.

2. PCB Fabrication

With your design files ready, it's time to bring the circuit board itself into existence. This stage involves producing the actual board, complete with its base material, copper layers, and etched pathways. You'll have a variety of material options at your disposal, including aluminum, flexible boards, and rigid-flex PCBs.

3. Component Sourcing

After the PCB manufacturing is completed, the next step is to procure the necessary components for assembly. This requires determining each required component and sourcing them from trustworthy suppliers. It's crucial to ensure these components are compatible with your design and meet the necessary quality standards.

4. PCB Assembly and Testing

The final stage involves assembling and testing the prototype PCB. This process includes mounting the components onto the board and soldering them securely. The assembled board is then rigorously tested to confirm it functions as intended and meets all the specified requirements.

Fully Traceable PCB Assembly Procedure

We maintain detailed records for each and every prototype PCB assembly project. We document the origin of every single component used in the production of your prototype printed circuit boards, as well as all the processes employed in their assembly.

ApplePCB guarantees full traceability of the assembly process. This traceability encompasses all PCB components and ESD packages, ensuring transparency from the point of supply to the final delivery. Consequently, you can track the progress of your prototype PCB assembly at each stage.

Our Prototyping Capabilities

ApplePCB has streamlined and refined the PCB assembly prototyping process. Through automation, we provide rapid and high-quality PCBA prototyping services. Even in cases where automation is not possible or when the prototyping requires high customization, we guarantee flawless delivery of your PCB assembly prototype.

We can produce a variety of components, including surface-mount devices (as small as 01005 inch-code), through-hole components, and mixed assemblies. When it comes to board types, you can choose from six standard PCB technologies encompassing rigid, flex, and rigid-flex options. These include FR-4, IS 400, IMS, Polyimide, CEM-3, and Rogers materials. We can also process printed circuit boards as large as 600x300mm. To simplify the process, upload your BOM and we'll directly verify component availability and pricing, ensuring the optimal selection for your project.

Engage with our expert Quote Team to swiftly obtain a detailed quote, typically within 24 hours, helping you adhere to stringent project timelines. With your go-ahead, we can procure the necessary components and bare boards, and assemble your PCBs in as few as 10 business days.

Our goal is to expedite the delivery of your PCB assembly prototypes, without compromising quality. Leveraging automated technology and sophisticated equipment, we assure reliable quality. Moreover, our assembly process is transparent, providing you with full traceability from start to finish.

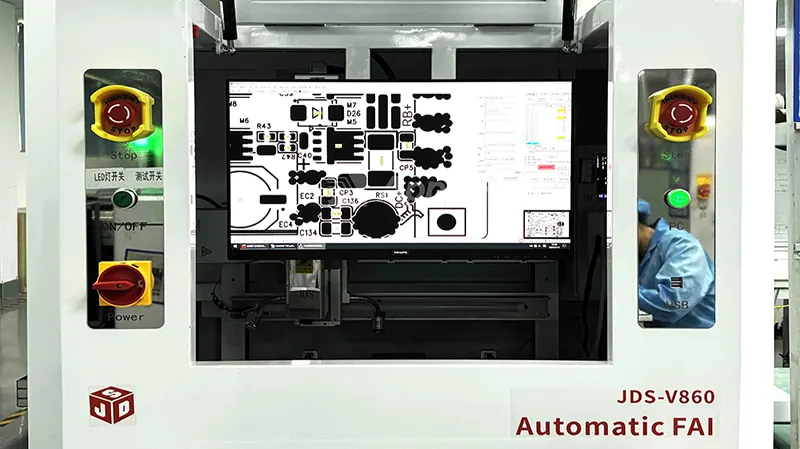

Our Assembly Equipment

We are located in Shenzhen with two manufacturing facilities equipped with the most sophisticated equipment necessary for PCB assembly. To learn more about our factory, please click here.

WHY US?

When you choose to collaborate with us for your PCB assembly needs, you gain access to a suite of quality assurance measures. We meticulously examine each PCB, visually scrutinizing for any inconsistencies in soldering, component placement, or other assembly aspects. Functionality testing ensures your PCB operates precisely as intended, meeting all performance benchmarks. Additionally, electrical testing guarantees adherence to the required electrical specifications, verifying the absence of any defects or flaws.

Beyond these fundamental testing and inspection methods, we utilize Automated Optical Inspection (AOI) and X-ray inspection. These technologies enable us to quickly and precisely identify any irregularities, allowing for necessary adjustments before your PCBs are delivered.

Should you need a dependable and seasoned provider for PCB assembly services, feel free to reach out to ApplePCB. Our professional team is ready to assist with your prototype PCB assembly projects, hoping to help you realize your designs.