Box build assembly, also known as systems integration, encompasses the creation of a fully operational system. This process involves taking a PCB and combining it with various components such as cables, din rails, backplane assemblies, and cabinet housing, resulting in a complete, enclosed unit.

The scope of box build assembly services is quite broad. It can range from placing a PCB assembly within a simple enclosure and connecting it to an interface, all the way to constructing a complex machine that incorporates a multitude of parts and sub-assemblies. Essentially, box builds encompass all assembly processes involved in electromechanical assembly, with the exception of PCB production itself.

These assemblies serve to connect multiple devices within a single electronically controlled system. ApplePCB's box build service encompasses both the design and interconnection of various PCBAs and devices. Our team develops and constructs box build assemblies tailored to each client's specific needs. This includes managing intricate wire and harness connections, cable connections, screen integrations, connector incorporation, switch installations, and more.

What is Included in a Box Build Assembly?

When considering a box build assembly, you are essentially looking at an enclosure containing various elements. These typically include printed circuit boards populated with electronic components, along with power supply units, wiring harnesses, and mechanical parts. Additionally, software, cooling and ventilation systems, connectors, sensors, and peripheral devices may be incorporated. The exact composition of a box build is determined by the specific needs of the client. At ApplePCB, we take the time to understand your individual requirements and conduct a thorough analysis to determine the appropriate internal components for your box build. We prioritize ensuring compatibility between all systems and mechanical elements within the assembly.

Advantages of Box Build Assembly

Opting for box build assembly presents several benefits for your manufacturing process, including the following:

Time Savings and Cost Reduction

By Box Build Assembly, you can achieve a faster production turnaround. Working with a single electromechanical service provider who possesses comprehensive knowledge of each component within the box build eliminates the need to coordinate with multiple vendors. This streamlined approach not only accelerates the assembly process but also minimizes communication delays and reduces overall manufacturing costs.

Quality Assurance and Supply Chain Simplification

Entrusting your box build assembly to specialists ensures the highest quality standards are maintained. These experts understand the intricate interplay between individual components, such as circuit boards and wire harnesses, guaranteeing optimal compatibility and performance. Furthermore, consolidating your assembly needs with one vendor simplifies your supply chain, leading to improved logistics management and reduced complexity.

Considerations for Your Box Build

To guarantee the success of your box build assembly, consider these fundamental factors:

Product Specifications

Communicate the exact dimensions and desired aesthetic of your final product to your chosen electronics manufacturing service (EMS) provider. Supplying detailed design drawings with clearly marked tolerances and clearances is essential. Additionally, inform the EMS provider of the finished unit's size and weight beforehand to facilitate efficient production, storage, and shipping processes.

Bill of Materials (BOM)

A comprehensive BOM listing all necessary components and materials is crucial. Specificity is key; clearly indicate the source of each material, distinguishing between those you will provide and those the EMS provider will procure.

Prototype Development

Opting for an EMS provider with in-house prototyping capabilities allows for invaluable insights into design functionality and potential areas for refinement. Engaging in prototyping before full-scale production helps identify necessary adjustments and prevents issues during the assembly phase.

Testing Protocols

Clearly outline the specific testing procedures required throughout the assembly process and for the final product. While visual inspections often suffice, certain functional thresholds might necessitate additional testing. Maintain open communication with your EMS provider to ensure they are fully aware of all electrical and functional testing requirements.

Box Build Assembly Process

In the box build assembly process, maintaining high-quality standards and thorough documentation is essential. Accurate records, such as component traceability, assembly procedures, and test outcomes, are kept to uphold product quality and support any future troubleshooting or maintenance needs. Below is an explanation of the steps involved in the box build assembly process:

Preparing the Enclosure

Initially, the enclosure or housing is prepared. This step involves checking for any imperfections or damage, conducting a thorough clean, and confirming the correct positioning of mounting holes and slots.

Integrating Components

Following the enclosure preparation, components are installed. This phase encompasses mounting and securing the PCBs, power supply units (PSUs), connectors, control panels, and any other necessary elements. Ensuring correct placement, fastening, and electrical grounding of these components is vital at this stage.

Electrical Wiring and Connection

After the components are in place, electrical wiring and connecting are undertaken. This includes routing and linking wires, cables, and harnesses to form electrical connections among the components. Special care is taken to manage routing, length, insulation, and fastening of the wires to guarantee reliable and orderly connections.

Integrating Subsystems

In cases where the assembly includes pre-assembled subsystems or modules, they are integrated at this juncture. This involves fitting components like communication modules, motor control modules, or other units tailored for specific functions.

Control and Testing

Upon completing the integration, the assembled product is subject to exhaustive testing and quality assurance checks. Functional, electrical, and performance evaluations are conducted to confirm its operation, conformity to design parameters, and regulatory compliance. Detected issues or anomalies are corrected at this point.

Final Assembly and Inspection

Following successful testing, additional elements like cooling fans, heat sinks, or covers are installed. A final check is then carried out to ensure the quality of the assembly, correct connections, alignment, and compliance with design criteria.

Packaging and Labeling

The concluding phase is packaging the fully assembled product or system, ensuring it is well-protected for transport and storage. The packaging process includes applying labels, branding, and user instructions to the packaging's exterior.

Why Choose ApplePCB for Box Build Assembly Services?

ApplePCB offers integrated PCBA box build assembly services. We handle SMT, BGA, and chip-scale packaging (CSP), among others. Additionally, we integrate these PCBAs into a finalized box build assembly, adhering to lead-free standards upon your request to meet RoHS compliance.

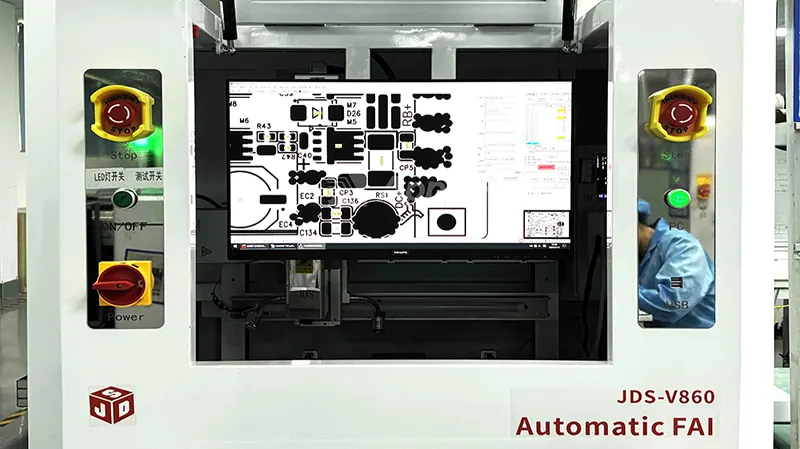

Our facility boasts advanced equipment, enabling us to construct intricate box build assemblies efficiently. Each assembly conforms to IPC 610 Class 3 standards, ensuring quality and reliability. Our internal quality assurance system guarantees thorough testing of your box build. The test engineering team develops a comprehensive test plan to validate your product.

We also support the initial design stages through design reviews, validation, netlist verification, end-of-life (EOL) components analysis, Design for Manufacturability (DFM) assessments, Design for Testing (DFT), and cost-effective Bill of Materials (BOM) preparation.

Our PCB Box Build Testing Capabilities encompass:

- Custom Test Fixtures and Test Beds

- Flying Probe and In-Circuit Test (ICT)

- X-Ray Inspection

- Device Programming (JTAG, BDM, etc.)

- Device and Assembly Serialization

- Comprehensive Functional Testing

- High Potential and High Voltage Testing

- Automated Optical Inspection (AOI)

- Boundary Scan Testing

- Voltage and Current Testing

- Custom Labels and Branding

- Systems Testing

- Dielectric Testing

- RF Testing

Our Assembly Equipment

We are located in Shenzhen with two manufacturing facilities equipped with the most sophisticated equipment necessary for PCB assembly. To learn more about our factory, please click here.

Request a Free PCB Assembly Quote From ApplePCB

When considering box build PCB assembly, consider engaging with ApplePCB. Our online quoting system simplifies the process, allowing you to quickly understand our capabilities. We take pride in providing a variety of services, spanning from prototyping to large-scale production.

Should you require box build and final assembly services and wish to know our offerings or discuss your specific needs, please contact us. Our team of PCB experts is willing to assist you and provide the necessary support.

Box Build Assembly FAQs

How long does it take to complete the box build assembly?

The box build process varies by project, influenced by the product's complexity. Some projects may involve a straightforward printed circuit board assembly within a housing, while others may necessitate complex connections to a user interface display. To determine the feasibility and establish a timeline, it is recommended that you initially discuss your specific requirements.

Providing comprehensive information, such as product dimensions, a bill of materials, and sample prototypes, can expedite the box build assembly process. Rest assured, we guarantee to deliver a high-quality assembly, regardless of project complexity.

How to choose a manufacturing partner for PCB Box Build?

When selecting an electronics contract manufacturer, it's essential to assess their capacity to deliver engineering and design support. This encompasses services like manufacturability analysis, software integration, and product configuration options, all crucial elements for a successful box build. Additionally, inquire about the manufacturer's internal resources, such as in-house personnel, a network of reliable suppliers, a prototyping team, relevant quality certifications, an internal testing department, and the ability to dropship directly to customers. A proficient contract manufacturer should demonstrably reduce production time and expenses while also offering design adjustments as needed.

What should I provide to the CM for PCB box build assembly?

When initiating a PCB Box Build project with a CM, providing complete documentation is key. This encompasses assembly drawings, schematics, a bill of materials, wire lists, and testing specs. While a CM can begin with just the bill of materials and schematics, doing so may overlook important information and subsequent delays due to additional communication. Therefore, to ensure a smooth and efficient build process, providing your CM with all relevant documentation at the outset is highly recommended.

Why should I choose ApplePCB for my business?

You can find significant time and cost savings by choosing our box build assembly services. We maintain high quality and performance standards throughout the process. Our approach emphasizes speed, efficiency, and accuracy. Additionally, we offer customized system integration designs to meet particular environmental requirements, ensuring the protection of delicate components from external contaminants.