As we all know, PCB solder mask is a protective coating that covers the surface of a PCB, most commonly in green colour. So what is its function? And what is a solder mask bridge? What is the mystery contained in its material? In addition, flexible PCB and rigid PCB manufacturing process what is the difference? And how can common problems be avoided in the manufacturing process? In this article, we will explore these issues in depth to help you better understand PCB solder masks.

What is PCB Solder Mask?

PCB solder mask is a non-conductive coating used to protect copper alignments on PCB. It mainly covers the top and bottom layers of the PCB solder mask. Only the parts that need to be soldered, such as pads and vias, are kept out so that electronic components can be soldered to the board properly. But apart from this, PCB solder mask has quite a few more functions.

PCB Solder Mask Function

1.Prevent Copper Trace Corrosion and Oxidation

Once exposed to air, copper oxidises over time, losing its electrical conductivity and structural integrity. Although copper's own oxidised layer can provide some short term protection, problem will still occur over time. Solder masks provide longer term protection against the environmental effects of copper traces, keeping the board in better condition.

2.Inhibit the Growth of Tin Whiskers

The solder mask also helps prevent the formation of tin whiskers. Those tin whiskers that can unexpectedly appear on a PCB and potentially lead to short circuits or other issue. Through covering the solder mask adequately inhibits the development of whisker efficiently.

3.Reinforcement of copper pads

The solder mask also provides additional structural reinforcement to the pads on the board, preventing the pads from separating from the PCB. This reinforcement is very important for flexible PCBs.

4.Improve Electrical Performance

Some solder mask (e.g. photoresist) are also a dielectric material, so it can increase the breakdown voltage of the PCB's dielectric layer.

Three Different Types of PCB Solder Masks

PCB solder mask are usually composed of thermosetting polymeric material with excellent thermal and chemical resistance. The following is a comparison of 3 different type of PCB solder mask and their property:

1.Epoxy-Based Solder Mask:

This particular solder mask is made by combining epoxy resins and a hardener to create a liquid coating that offer adhesion and outstanding chemical resistance property at a price point. It can shield the PCB from chemical during the manufacturing and assembly process.

2.Acrylic-Based Solder Mask

Acrylic-based solder mask consist of acrylic monomer, photoinitiator and functional additives, and has good flexibility. It can be bent without cracking or delamination, so it is often used in flexible and rigid-flexible PCBs.

3.Ethyl Carbamate-Based Solder Mask

This solder mask balance the characteristics of epoxy resin and acrylic, both good flexibility and chemical resistance, able to withstand high temperatures and chemical corrosion. It is suitable for PCBs that require some flexing but at the same time maintain the reliability of the solder joints and pads.

| Property | Epoxy-based | Acrylic-based | Urethane-based |

| Adhesion | Excellent | Good | Very Good |

| Chemical Resistance | Excellent | Good | Very Good |

| Flexibility | Low | Excellent | Good |

| Thermal Resistance | High | Moderate | High |

| Dielectric Strength | High | Moderate | High |

What Is a Solder Mask Dam?

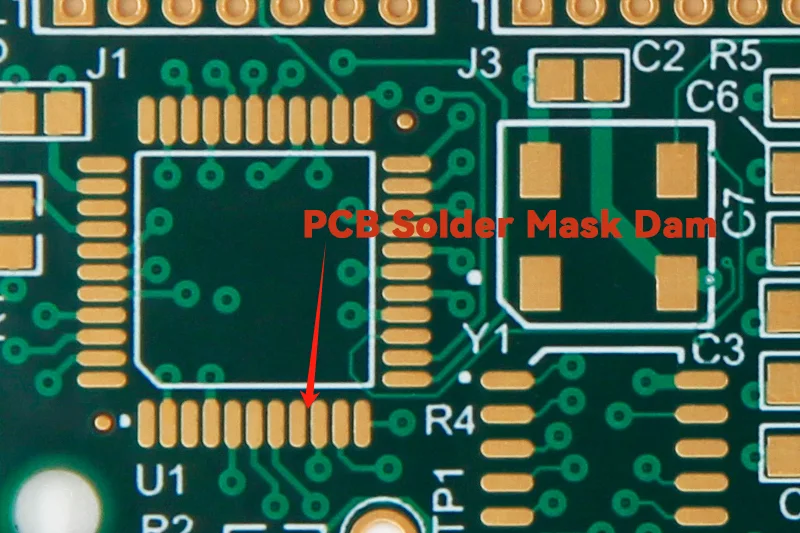

A solder mask dam, also known as a solder mask bridge, is a small portion of the solder mask on a PCB that is used to form a small barrier around each pad or via hole. Its main function is to prevent solder from flowing from one solder joint to another during assembly to avoid electrical short circuits.

The types of solder mask dams can be categorised into the following three types:

1.Open Solder Mask Dams

It is the most common and easiest to solder mask dam by leaving a small open area around the pad or via hole, so that solder can reach it target area without spreading to other areas on the PCB.

2.Shadow Masked Solder Dams

Similar to the open type, but it creates a barrier around the pads or via holes through a diagonal pattern. This diagonal creates a small gap that allows solder to flow onto the pad or via without spreading.

3.Circular Solder Mask Dam

As the name implies, the circular solder mask form a ring around a pad or via hole to contain solder and prevent it from spreading outwards.

| Features | Open Solder Mask Dams | Shadow Masked Solder Dams | Circular Solder Mask Dam |

| Difficulty | Simple | Moderately Complex | Complex |

| Solder Protection | Basic Protection | Higher Protection | Maximum Protection |

| Applicable Component Density | Normal PCB or Wide Pitch s | Closely Spaced Components, High Density PCBs | Fine Pitch Components, Complex High Pin Count s |

How to Prevent Bad Solder Mask Dam?

1.Properly ed Mask Relief: In solder mask relief , make sure that areas that do not require solder mask are kept clear and adjust the size of the relief according to the spacing of the components. Usually the release slot value should be between 0.003 and 0.008 inches to prevent the occurrence of solder bridging.

2.Reasonable use of solder mask Dam: The of a solder mask between closely spaced pads (solder dam) is an effective means of preventing solder bridging. However, the should ensure that the size of the solder mask is reasonable. The following is ApplePCB's solder mask dam production process capability

| finish copper | green | other colour |

| finish copper≤1oz | 4mil | 5mil |

| finish copper≤2oz | 7mil | 9mil |

Of course, in addition to the , PCB solder mask manufacturing process should also pay extra attention to effectively prevent solder bridging problems.

3.Optimise the reflow process: Adjusting the reflow profile can effectively prevent solder bridging problem. By extending the time at slightly above the melting point of the solder can help pads and component pins gradually reach the required temperature, thereby promoting proper wetting and adhesion of the solder to avoid the spread of solder to unnecessary areas.

4.Control solder paste volume: By adjusting the stencil and reducing the amount of solder paste used, we can better control the area and size of the solder paste applied. This can greatly reduce solder bridge problem in those components closely spaced area.

ApplePCB's Advanced PCB Solder Mask Manufacturing Technology

1.Liquid Epoxy Solder Mask

This type of solder mask is a liquid epoxy resin that is applied to the PCB by screen printing. The epoxy resin hardens during the curing process and forms a protective layer. Due to its low cost, it is the most common choice for PCB that need to be produced in large quantities.By adding solder mask dyes, Liquid Epoxy Solder Mask can be formed into our desired colour, the common colour are green, blue, red, etc.

2.Liquid Photo-Imageable Solder Mask (LPSM)

This more advanced technology is similar to photolithography exposure in semiconductor manufacturing, using liquid solder mask or dry film. LPSM can be applied by screen printing or spraying. LPSM can be applied by screen printing or spraying. The solder mask is formed when the board is covered with LPSM and then baked, developed, exposed and cured in a number of processes.

The advantage of Liquid Photo-Imageable Solder Mask are that it provides higher resolution and fine line definition, and is able to create more complex pad, via, and opening for high precision PCB . In addition, it has a higher degree of adaptability to various substrates, with better adhesion, significantly improving the reliability of PCB solder mask. It is worth noting that ApplePCB's LPSM process has developed a low-temperature curing formula, which can effectively reduce the thermal stress of PCB components. And we can effectively shorten processing time and improve productivity by curing the solder mask with LEDs.

3.Dry Film Solder Mask (DFSM)

Similar to LPSM, DFSM use photolithography to apply the solder mask. The difference is that DFSM use a pre-formed photopolymer film for vacuum lamination. The dry film solder mask have a faster processing speed than LPSM, make it ideal for high volume production. In addition, because it is made by laminating a preformed photopolymerised film, the solder mask achieve a more accurate thickness and a more uniform surface, making it suitable for PCB that require tight tolerance control or have specific electrical requirement.

4.Emerging Solder Mask Application Technology

In addition to the above mentioned three kinds of solder mask, in the PCB industry there are also some promising solder mask technology, their common advantage lies in the high precision and high flexibility, can cope with the increasingly complex PCB .

- Inkjet printing solder mask technology: This is a non-contact deposition technology, the use of inkjet printing technology to digitally control the way the precise deposition of solder mask on the PCB surface. This method enable high-precision printing with line widths as small as 50 μm.

- Laser Direct Imaging (LDI) technology This is the use of laser light in combination with photosensitive solder mask material for direct maskless imaging. It achieve a resolution (less than 30 μm) that exceed that of conventional lithography and reduce the number of processing step. However, specialised photosensitive solder masks and expensive equipment are a major challenge.

- 3D printed solder mask technology: This is an advanced solder mask technology that incorporate 3D printing. It is extremely flexible and can be customised in term of thickness and topography to create 3D solder mask structure. Although this technology show promising applications, developing 3D printed materials that meet the performance requirements of solder masks remains one of the main technical challenges.

Differences in Solder Mask for Flexible PCBs

While rigid and flexible PCB are similar in most manufacturing processes such as drilling, plating, and developing, there are significant differences in solder mask processes. For flexible PCB, conventional liquid solder mask and manufacturing processes may not be able to meet the demand for further flexibility. Therefore, flexible overlay have become the preferred solution for flexible PCB instead of traditional solder masks.

Unlike the rigid PCB solder mask manufacturing process, the flexible PCB cover layer do not need to be coated by screen printing or spraying liquid solder resist as mentioned above. It is first drilled, wired, punched or laser cut according to the of the flexible PCB so that the overlay film can be aligned with the copper layer. A polyimide film coated with a thermosetting adhesive is then laminated directly to the PCB surface. This manufacturing process allows the copper foil of the flexible PCB to withstand frequent bending and stress, meeting the more flexible requirements of flexible PCB.

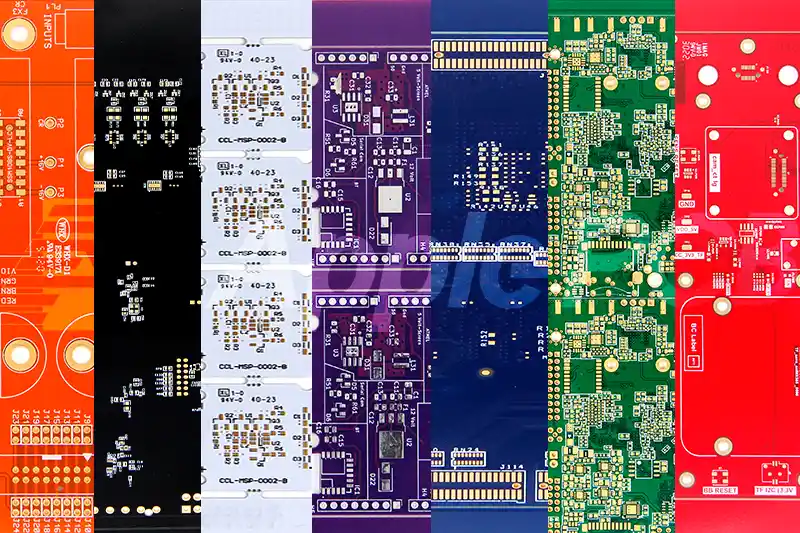

Different PCB Solder Mask Colors

The most common solder mask colour is green, which has a long history and a very mature manufacturing process. The characteristic of green solder mask is its visual comfort, neither too harsh nor too dark, easy to follow the manual inspection. In addition to green, we can also choose other colours.

●Black Solder Mask PCB

Black PCB solder mask is often seen as a symbol of high-end, because early first-tier PCB manufacturers often use black solder mask in high-end products, and from the visual point of view, black gives a more professional and advanced feeling. In addition to the advantages of appearance, black solder mask also has excellent electrical performance, thermal stability and electromagnetic shielding capabilities, especially favoured by the LED device.

However, black PCB also has disadvantages, such as easy to cause visual fatigue, increase the difficulty of appearance detection, and circuit alignment is not easy to identify, the R & D and maintenance stage may be more complex.

●Blue Solder Mask PCB

Blue PCB solder masks are popular for their novel appearance and good contrast. However, in practice, blue solder masks are difficult to manufacture. Because blue ink is more fluid, it is easy to accumulate oil and uneven during production, and it is more difficult to plug holes for operation. Its hardness is also not as good as the green solder mask, easier to be scratched, the production of defective rate is higher. In addition, the blue solder mask baked board for a long time, easy to become dirty and discolouration in use, especially after the use of flux. However, the Nissan Blue Oil provided by ApplePCB can solve these problems to a certain extent.

●Red Solder Mask PCB

Visually, red is also popular with PCB engineer as it is a bold and vibrant colour that can make PCB more noticeable. Red solder mask PCB also have good contrast, enabling us to detect error and bad solder joints on PCB more easily. In addition, red solder mask is lead-free tin, so it is very environmentally friendly.

●White Solder Mask PCB

White PCB solder mask has the advantage of a visually clean, high end appearance, but it also has some disadvantage. Due to its reflective nature and colour, circuit trace are not easily discernible, especially in well-lit environment where glare is likely to occur, making inspection difficult. Therefore, white solder mask is usually paired with black screen printing to enhance contrast. It ideal for lighting device such as LED board.

However, it should be noted that the colour of the white solder mask may vary from supplier to supplier, so you need to be clear about your own requirement for "white" when choosing. ApplePCB will be happy to provide you with samples of our product so that you can compare and select the "white" you want.

●Other Colours Solder Mask PCB

In addition to the above colours, there are also purple, yellow, orange, pink and even multi-colour solder masks available, ApplePCB has done multi-colour solder mask PCBs.(below) Since, these colours PCBs are not very common, there is a need to communicate effectively with the PCB manufacturer's team to balance the different requirements of different colours, such as cleanliness, visibility and style, visibility and style etc.

Choose Between Glossy Finish or Matte Finish?

In addition to the colour, we can also choose the texture of the finish. In general, the choice of glossy or matte solder mask depends mainly on the appearance and actual manufacturing requirements.

Glossy finish has a smoother surface that give the PCB a glossy, high end look and is less likely to show sign of damage. It is also harder and therefore more resistant to scratches than matte finish. The matte solder mask surface is non reflective and look softer and lower profile, which help to reduce glare and is suitable for appearance check. Correspondingly matte will also be more likely to show sign of wear and tear. However, there are corresponding studies that show that the risk of solder balling is reduced due to the lower level of gloss on matte PCB.

If you do not specify, the PCB manufacturer will default to a glossy finish. If you need to produce a matte finish, then you need to speak to the manufacturer in good time to ensure their manufacturing capabilities and quality control.

ApplePCB's Solder Mask Manufacturing Capability

| Solder Mask Brand | KSM-S6189(green, black, yellow, red, blue, matte green, matte black) Taiyo PSR-4000 G23K (green) ABQ RS-2000 V-5 (purple) |

| Solder Mask Colour: | green, yellow, black, blue, red, white, orange, purple,pink. matte green, matte black etc |

| Solder Mask Cover Trace: | 2mil (allow partly 1.5mil) |

| Solder Mask Dam: | Finish copper≤1oz: 4mil=green, 5mil=other colour. |

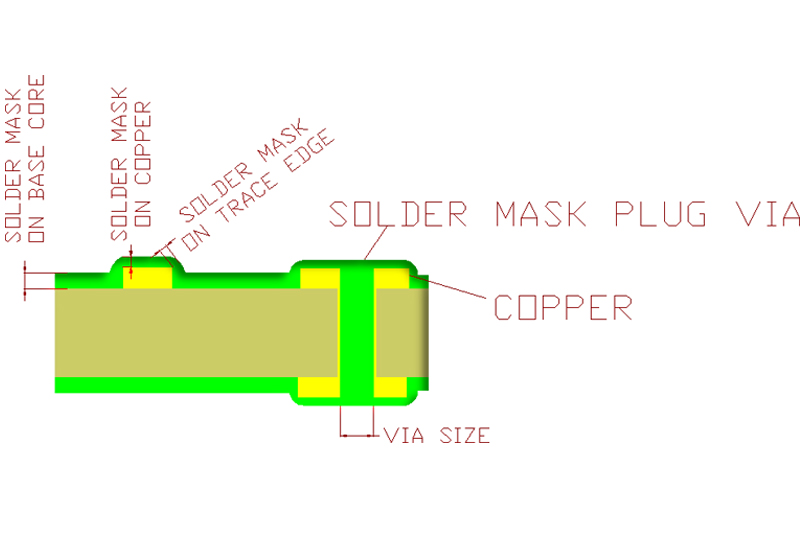

| Solder Mask Thickness: | Max:25um (print two times) Standard(print one time): Copper plane area:10-18um, Via edge:≥5um, Copper trace edge:≥5um. |

| Max via Size for Plug Solder Mask: | 0.5mm |

Final Thoughts

With the continuous development of solder mask technology, such as LPSM, DFSM as well as emerging technologies such as inkjet printing and 3D printing, more option are available for the efficient manufacturing of modern complex circuits. With 15 years of experience and advanced solder mask application technology, ApplePCB can provide you with high-quality solder mask inks as well as a wide range of solder mask colour to choose from selection. Please feel free to contact us with your solder mask project need or any other PCB manufacturing related questions!