After you invest time in perfecting your PCB design, waiting weeks or even months for the manufactured version is likely not the outcome you desire. You need a fast turnaround time to start using your PCB as soon as possible.

Our quick turn PCB prototyping and assembly service delivers orders promptly while maintaining high quality. This service is ideal for saving both time and money, with lead times as short as 24 hours or even the same day. If speed is less critical, you can choose from other lead times, such as 48 or 72 hours.

We have an efficient response mechanism to expedite your order from quotation to delivery. Our entire fast-turn process is handled internally, ensuring smooth operations without outsourcing.

Benefits of Fast Turn PCB Assembly

Reduced Time to Market

Assembling your PCBs quickly allows you to bring your product to market much sooner. This can offer you a competitive edge and help you take advantage of timely market opportunities.

Faster Prototyping

Speed is critical in prototyping. Fast turn PCB assembly enables you to swiftly test and refine your designs, allowing for quicker modifications and improvements.

Enhanced Flexibility

With fast turn PCB assembly, your production schedule becomes more adaptable. You can promptly respond to changes in demand, adjust production capacity as needed, and seize new market opportunities.

Cost Savings

This approach can lead to significant cost savings. By shortening the time to market, you can start generating revenue sooner. Additionally, faster prototyping helps avoid costly design errors and rework.

Increased Customer Satisfaction

Fast turn PCB assembly helps you meet customer expectations by delivering high-quality products in a shorter timeframe. This can enhance your reputation for reliability and excellent customer service, fostering repeat business and referrals.

Quick-Turn PCB Prototyping Process

Submitting Your Design

You should submit your design files to the manufacturer for evaluation. This includes Gerber files, centroid files, and any specific requirements such as a bill of materials.

Ensuring Manufacturability

Before material selection, the manufacturer conducts a Design for Manufacturability (DFM) check. This verifies that your design can be produced efficiently, preventing potential production issues and ensuring a smooth manufacturing process.

Material Selection and Inventory Verification

At this stage, the manufacturer checks the inventory to ensure all necessary materials, including PCB components and substrates, are available.

Prototype Production

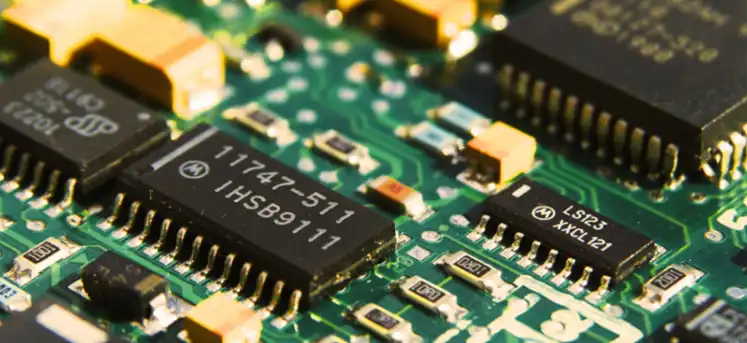

The manufacturer then uses advanced production techniques to rapidly produce and assemble the prototype according to your specifications.

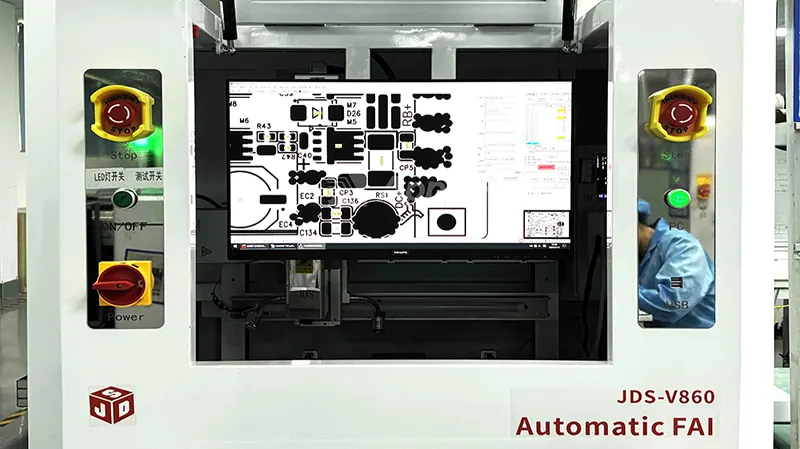

Quality Assurance and Testing

Following production, rigorous quality control and testing commence. The manufacturer verifies that each PCB meets your specifications and functions effectively as a high-quality product.

Shipping and Delivery

Once the quality testing phase is complete, the prototypes are packaged and shipped to you. You then evaluate the prototype PCBs and provide any necessary feedback to the manufacturer.

Quick Turn PCB Assembly Services

With a wealth of experience in producing PCB prototypes and managing production runs of varying volumes, ApplePCB is your go-to for projects with demanding timelines. Our skilled assembly team ensures your PCB designs are realized promptly and effectively. We guarantee the timely delivery of your PCB orders and ensure the highest quality from prototype production through to low to medium volume production runs.

We offer the shortest lead times in the industry. For prototype PCBs, you can select lead times of 24/48 hours or 5/10 days. For low-volume production orders, you have options of 10, 15, or 20 days. Mid-volume production orders are completed in 15, 20, or 25 days.

Using the latest in surface mount and through-hole technology, we handle a diverse array of PCB types, including SMT, through-hole, and mixed technology. We also provide BGA rework and X-Ray testing services. We can assemble single-sided or double-sided PCBs with surface mount packages.

At ApplePCB, quality is paramount. We will never compromise quality for speed. Our rigorous testing procedures ensure that your PCB is not only made from the finest materials but also that every component functions perfectly.

Our Capabilities in Quick Turn PCB Assembly

We offer quick turn PCB assembly services that meet the needs of our customers. Our capabilities include:

Board Types

- FR4 Rigid Boards

- Flex Boards

- Rigid-flex PCBs

Solder Types

- Lead-free/ROHS compliant

- Leaded/ROHS compliant

Parts Acquisition

- Full Turnkey

- Partial Turnkey

- Kitted/Consigned

Assembly Types

- Surface Mount (SMT)

- Thru-hole

- Mixed Technology (SMT/Thru-hole)

- BGA Assembly

- Single or double sided placement

Surface Finishes

- SMOBC/HASL

- Electroless Nickel Immersion Gold (ENIG)

- Lead-free HASL

- Immersion Silver

- Immersion Tin

Testing and Inspection

- Visual Inspection

- AOI Inspection

- X-Ray Inspection

- In-circuit Test

- Functional Test

Why Us for Quick Turn PCBs Assembly?

We recognize the need for rapid market entry, so we ensure the fastest possible delivery for your quick turn printed circuit boards. Depending on the complexity of your requirements, you can receive your PCBs within 24 hours or within 2 to 3 business days.

Please provide your specifications for prototype and co-op panels to receive a prompt quote. For a custom quote, we need certain details from you, including the desired thickness, copper weights, solder mask colors, and surface finishes of your PCBs.

You can rely on our responsive and reliable customer service and transparent communication. To obtain a quick quote for PCB assembly, simply email your BOM in Excel format, required quantities, and Gerber files to [email protected].