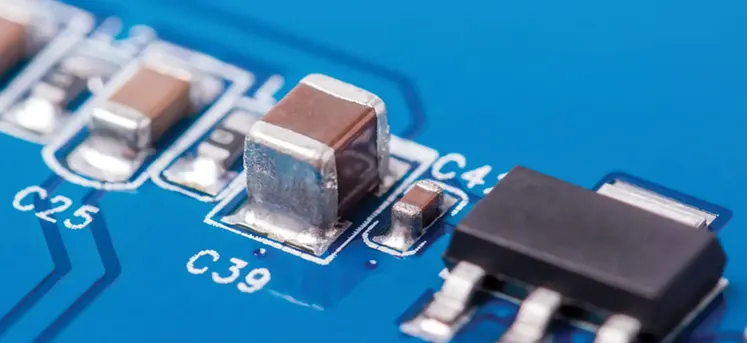

Surface Mount Technology (SMT) is a method used in assembling PCBs. Unlike the older Through-Hole Technology (THT), which requires drilling holes for component placement, SMT allows components to be directly soldered onto the PCB surface. This results in smaller, more efficient, and cost-effective electronic devices.

ApplePCB has extensive experience providing high-quality SMT assembly services to clients across various industries. We specialize in contract manufacturing and possess the expertise to assemble electronics for a diverse range of applications. Our advanced equipment of equipment and highly skilled staff enable us to support your project from prototyping and testing to mass production.

Whether your project requires small batches or high-volume SMT assembly, we are dedicated to delivering the highest quality product. We achieve this through our vast experience, commitment to continuous improvement, and utilization of surface mount devices (SMDs) which optimize both performance and cost-effectiveness.

Understanding SMT PCB Assembly

In SMT assembly, electronic components are directly attached to the surface of PCBs using a technique called batch solder reflow. Let's break down the steps involved:

1. Applying Solder Paste: The designated areas on the PCB receive a precise application of solder paste, a sticky substance containing tiny solder particles.

2. Component Placement: Using automated machinery, the components are carefully positioned onto the solder paste.

3. Reflow Soldering: The entire assembly enters a reflow oven, where controlled heat melts the solder paste. This molten solder forms connections between the components and the PCB.

4. Cooling and Solidification: As the assembly cools, the solder solidifies, creating strong bonds that secure the components in place.

SMT assembly offers significant advantages, particularly for large-scale production:

● Automation: The process is largely automated, leading to reduced labor costs and increased efficiency.

● Miniaturization: SMT components, known as Surface-Mounted Devices (SMDs), are significantly smaller and lighter than traditional components. This allows for more compact and lightweight electronic devices.

● Improved Electrical Performance: SMDs have shorter leads, resulting in lower inductance and capacitance, which can enhance the electrical performance of the circuit.

However, some challenges are associated with SMT assembly:

● Technical Expertise: Operating and maintaining the sophisticated equipment demands skilled personnel. Additionally, any manual rework necessitates skilled technicians.

● Moisture Sensitivity: SMDs are more prone to moisture-related damage than traditional components. Proper handling and storage are crucial.

SMT assembly comes in three main types:

● Type I: This type exclusively utilizes SMDs, mounted on either one or both sides of the PCB.

● Type II: This type combines SMDs with through-hole components, often employed when certain components are unavailable in SMD format. This type involves the most intricate manufacturing process due to the diverse components involved.

● Type III: This type replaces only specific discrete components (like resistors and diodes) with their surface-mount counterparts. Typically, these surface-mount components reside on the underside of the PCB, while through-hole components occupy the top side.

Materials Utilized in SMT Assembly

The SMT assembly process relies on several key materials to ensure the proper placement and soldering of components onto printed circuit boards. These materials include solder paste, flux, adhesive, cleaning agents, and heat transfer mediums. Each plays a critical role in achieving reliable and functional electronic assemblies.

Solder Paste

This material serves the dual purpose of both soldering and temporarily adhering surface-mount components (SMCs/SMDs) to the PCB. Common solder paste compositions include Sn63/Pb37 and Sn62/Pb36/Ag2, which offer well-rounded performance characteristics. For applications requiring lower melting temperatures, Sn43/Pb43/Bi14 is often utilized. Additionally, Sn-Pb intermetallic compounds (IMCs) are favored for their strength and ability to readily wet surfaces, making them ideal for specific soldering needs.

Flux

This material facilitates the soldering process by promoting smooth and effective solder flow. Flux comes in two primary types: acid and resin. Both types work to remove oxides and contaminants from metal surfaces, thereby enhancing the solder's ability to wet and bond with the components.

Adhesive

As its name suggests, adhesive plays a crucial role in securing SMDs in place during the SMT assembly process. This prevents components from shifting or falling off the board before and during soldering.

Cleaning Agents

After the soldering process, cleaning agents are used to remove any residues left behind by the solder paste and flux. These agents must be chemically stable and exhibit thermal resistance to avoid decomposition during storage or application. Additionally, they should not react with other chemicals or corrode the components on the board. Ideally, cleaning agents should also be non-flammable and have low toxicity for safe handling. The cleaning process itself should be efficient and cause minimal loss while effectively removing residues within specified time and temperature parameters.

SMT Process

The assembly of PCBA involves affixing electronic components to the boards. SMT stands out as a widely adopted method in the electronics sector for PCBA. SMT components are mounted directly on the PCB's surface instead of being inserted into pre-drilled holes, a method known as through-hole technology. SMT enhances the assembly speed, improves efficiency, and accommodates smaller components, which can be placed more closely together.

Circuit Path Creation

The PCB, made from a non-conductive material like fiberglass or plastic, starts the SMT assembly. Copper lines on the PCB create pathways for electric flow. These lines are formed through photolithography, where light shines through a mask stencil to etch the trace patterns onto the board.

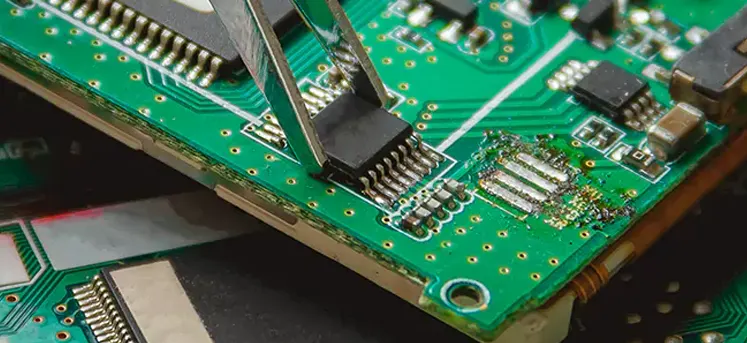

Component Placement

After preparing the PCB, the next phase is affixing the electronic parts. This is done with automated pick-and-place machines, which rapidly and precisely place components like transistors and resistors.

Optical Inspection

Post-placement, the PCB undergoes an Automatic Optical Inspection (AOI) to verify the placement accuracy of the components and identify any missing or misplaced parts. AOI involves using high-resolution cameras to compare the PCB against a predefined design to spot any differences.

Soldering Process

Soldering fixes the components onto the PCB, achieved through a reflow oven that melts solder under each component for secure attachment. Selective soldering may be used for more complex PCBs, targeting solder to specific board areas.

Quality Assurance

Following soldering, the PCB is inspected again via AOI to assess solder quality, with any soldering defects corrected through rework.

Advanced Inspection

Some processes might include an X-ray inspection for a deeper quality check, especially vital for detecting hidden issues like solder bridges or voids in dense or intricate PCBs.

Final Stages

After these inspections, the PCBA is washed, prepared for shipment, or assembled into larger products, like computers or phones, completing the manufacturing cycle.

ApplePCB's SMT Assembly Capabilities

We possess six fully automated high-speed SMT production lines. This allows us to handle a variety of complex projects with efficiency and accuracy. Our sophisticated SMT assembly equipment includes:

● Automatic board loading machines

● Automatic solder paste printing machines

● Solder paste thickness detectors (SPI)

● Multi-temperature zone reflow soldering machines

● Automatic optical inspection (AOI) equipment

● X-Ray inspection machines

● Baking machines

● PCB stencil cleaning machines

This advanced technology allows us to meet your specific SMT assembly needs, including the precise mounting of:

● 0201 components

● 0.3mm Pitch BGAs

● QFNs

We are also adept at assembling both single and double-sided SMT PCBs with various components, such as:

● Ball Grid Arrays (BGAs)

● Ultra-Fine Ball Grid Arrays (uBGAs)

● Quad Flat Pack No-Leads (QFNs)

● Quad Flat Packages (QFPs)

● Small Outline Integrated Circuits (SOICs)

● Plastic Leaded Chip Carriers (PLCCs)

● Package-On-Package (PoP)

● Small Chip Packages (Pitch of 0.2 mm)

Stringent Testing and Inspection:

Every PCB undergoes comprehensive testing and inspection, including 100% AOI of surface mount assemblies. We employ a meticulous evaluation process to guarantee the highest quality standards, including:

● Vibration and shock testing

● Scanning electron microscopy (SEM)

● Cross-sectioning, specimen preparation, and evaluation

● Humidity and temperature testing

Environment Chamber:

Temperature and humidity are critical factors that can adversely affect the assembly process. To mitigate their effects, we rigorously regulate and monitor these conditions in our facility. Additionally, we implement measures to shield the delicate electronic parts on the printed circuit board from Electrostatic Discharge (ESD).

WHY US?

With over a decade of experience, ApplePCB has established itself as a dependable service provider for SMT printed circuit board assembly. Whether you require large-scale production or prototype assemblies for upcoming product launches, we are totally equipped to handle it. Just share your specific requirements with us and we promise to customize it to your needs.

For further information regarding our surface mount assembly services, please don't hesitate to contact us. Our specialists are ready to assist you with precise specifications and cost-effective solutions for surface mount PCB assembly. We look forward to collaborating with you on your next project.